Utilizziamo i cookie per rendere migliore la tua esperienza di navigazione. Per rispettare la nuova direttiva sulla privacy, è necessario chiedere il tuo consenso per impostare i cookie. Dettagli

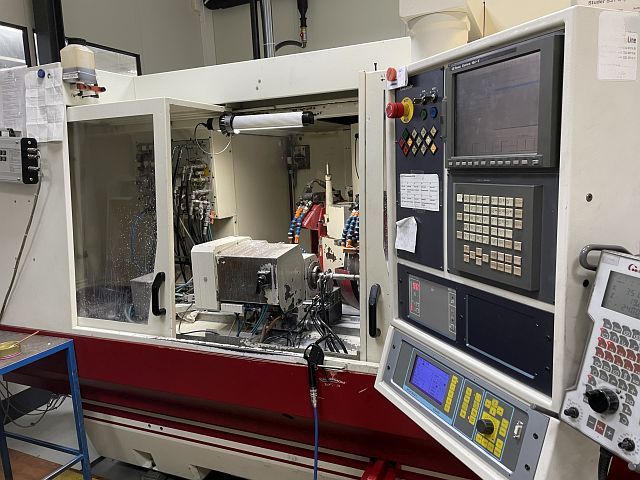

STUDER S 31

Categoria

Cylindrical Grinder - Universal

Oggetto

51467

Fabbricante

STUDER

Modello

S 31

Anno

2000

Controllo

GE FANUC 16IT

Oggetto

51467

| Working Range Cylindrical Grinding | ||

|---|---|---|

| diametro del pezzo (max): | 340 | mm |

| workpiece weight between centers (max): | 80 | kg |

| Working Range External Grinding | ||

|---|---|---|

| grinding diameter (max): | 340 | mm |

| Lunghezza rettificabile: | 650 | mm |

| Workpiece Spindlestock | ||

|---|---|---|

| asse c: sì | ||

| tailstock | ||

|---|---|---|

| distance betw. centers (max): | 650 | mm |

| Spindlestock Grinding Spindle | ||

|---|---|---|

| percorso di traslazione asse X: | 370 | mm |

| percorso di traslazione asse Z: | 800 | mm |

| tilting range (B-direction) min: | -30 | ° |

| asse-B rotante fino a: | 225 | ° |

| gamma di velocità (min): | 1 | /min |

| gamma di velocità (max): | 1500 | /min |

| Grinding Tool | ||

|---|---|---|

| type of grinding tool: wheel | ||

| diametro (max): | 500 | mm |

| borehole: diameter: | 203 | mm |

| larghezza: | 63 | mm |

| Spindlestock Internal Grinding | ||

|---|---|---|

| gamma di velocità (max): | 30000 | /min |

| Dati elettrici di collegamento | ||

|---|---|---|

| Potenza di collegamento: | 20 | kVA |

| Tensione di collegamento: | 400 | V |

| Frequenza della rete: | 50 | Hz |

| Misure / pesi | ||

|---|---|---|

| Requisiti spazio -sinistra/destra-: | 5000 | mm |

| Peso totale approssimativo: | 9500 | kg |

| attachments (grinding) | ||

|---|---|---|

| internal grinding spindle: sì | ||

| Equipment: 2 external grinding spindles 1 internal grinding spindle Fischer MFV 1230, 30000 1/min - C-axis for curve or polygon grinding (incl. HSM option) - Dressers: 1x fixed diamond on the tool holder, 1x dressing spindle on the tool holder, 1 swivel dresser - Studer Quickset, - Movomatic ES400 connection for measuring unit, (without measuring probe) - 1 tailstock, - 1 swivel dresser, - The machine can be converted to a jaw chuck - No water treatment, as it is installed on a central system |

| Equipment: 2 external grinding spindles 1 internal grinding spindle Fischer MFV 1230, 30000 1/min - C-axis for curve or polygon grinding (incl. HSM option) - Dressers: 1x fixed diamond on the tool holder, 1x dressing spindle on the tool holder, 1 swivel dresser - Studer Quickset, - Movomatic ES400 connection for measuring unit, (without measuring probe) - 1 tailstock, - 1 swivel dresser, - The machine can be converted to a jaw chuck - No water treatment, as it is installed on a central system |